E-Z STITCH HAS A NEW OWNER and will be in transition until around February 20th. At that time E-Z Stitch products will become available from these websites: adp-usa.com, ezstitch.net, stitchystash.com and other participating retailers.

Solving Fabric Tension Issues with your Scroll Frame

- Inspect Your Rods and Knobs.

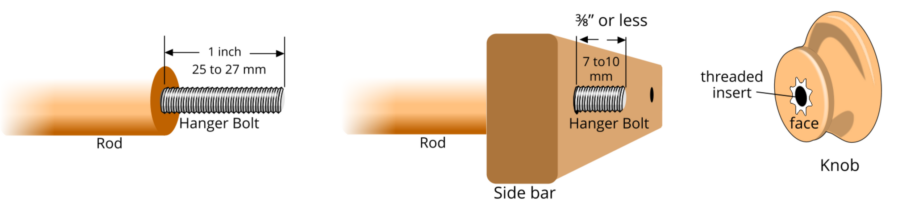

Although faulty rods or knobs are not the most common reason for fabric losing tension, they should be the first thing to rule out. The threaded hanger bolt should be firmly centered in the rod and extend about 1 inch (25 to 27 mm) from the rod end. When the bolt is inserted through the hole of a sidebar, it should protrude around ?” (7 to 10 mm). Check the threads on the hangerbolt for any damage. Ensure that the threaded insert of the knob is flush with the face of the knob. If any problems are detected at the time of purchase, please contact American Dream Products.

- Use Technique for Tightening Fabric.

The purpose of tightening knobs is to keep the rods from turning while you are stitching. When used properly, the wooden knobs (included with EZ Stitch frames) perform this function well on most types of projects.

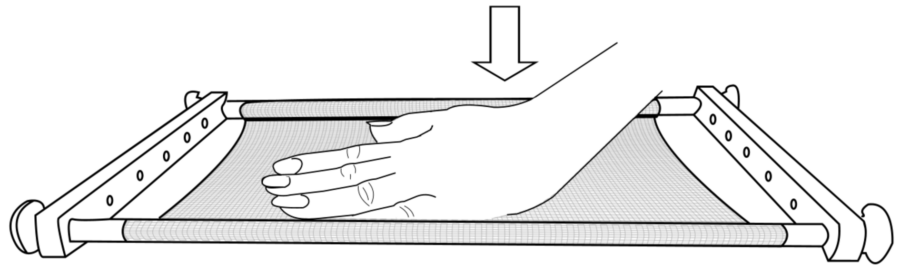

Follow these steps to increase the fabric tension: 1) Tighten the knobs (don’t over tighten). 2) With your palm, press on the face of the fabric. This will tighten the fabric rolled around the rods and move the slack to the center of the fabric. 3) Loosen the knobs on one rod and rotate the rod until the slack is removed. 4) Repeat steps 1-3 until you achieve the desired tension. Then, tighten all knobs.

- Is the Rod Turning?

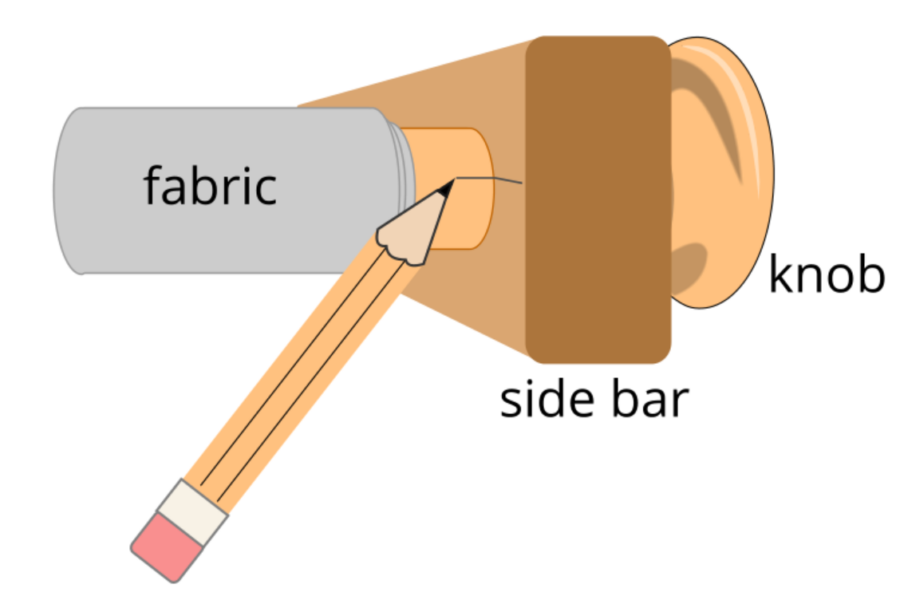

It is common for the fabric inside the frame to loosen while working on your project. In most circumstances, this is not due to the rods and knobs loosening, but rather the remaining slack in the rolled fabric being transferred to your workspace. Occasionally, you may need to repeat the steps above to remove the additional slack and achieve your desired tension. You can verify whether or not the rod is turning by marking a reference line (with a pencil). If you find that your project demands more tension to keep the rods from rotating, then we recommend using E-Z Stitch Tension Knobs. These industrial-strength knobs and rubber washers are designed to apply significantly more tension.

- Compensate for Density Variations

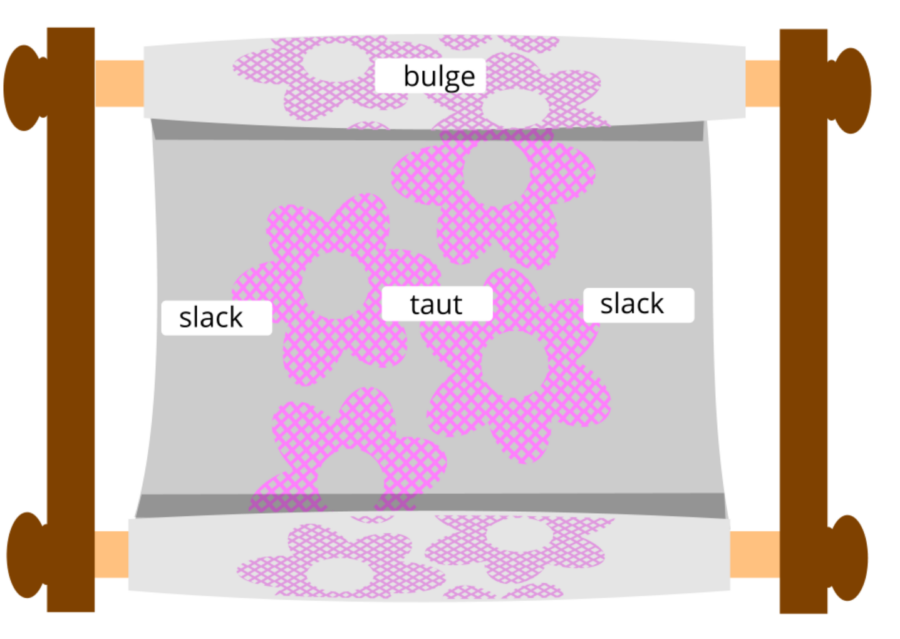

By stitching and embelishing, you add mass to the fabric, which is usually more concentrated toward the center of your frame. When this embellishment is wrapped around the scroll rods, it creates greater tension toward the middle of your project than on the edges. Stretchy or printed fabrics can cause similar variations in tautness. Because of this imbalance, it is difficult to achieve tautness along the edges by simply putting more pressure on the scroll rods.

By stitching and embelishing, you add mass to the fabric, which is usually more concentrated toward the center of your frame. When this embellishment is wrapped around the scroll rods, it creates greater tension toward the middle of your project than on the edges. Stretchy or printed fabrics can cause similar variations in tautness. Because of this imbalance, it is difficult to achieve tautness along the edges by simply putting more pressure on the scroll rods.

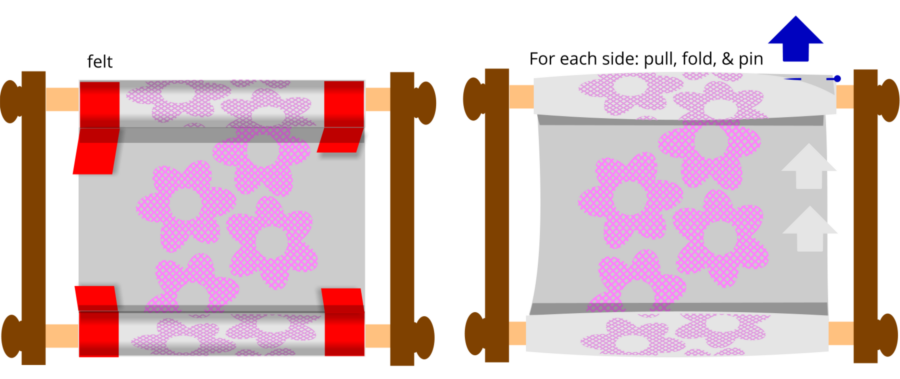

The best way to solve this issue is by evening out the tension. This can be achieved by either adding mass to the edges (such as a piece of felt) or pinning the edges in place as the fabric is rolled onto the rods.